Medical Device Manufacturing Software | Streamline Operations with Praxedo

Streamline Medical Device Manufacturing with Praxedo’s Software Solution

Optimize your medical device manufacturing processes with Praxedo’s comprehensive software solution.

Medical Device Manufacturing Software

Optimize your medical device manufacturing processes with Praxedo’s comprehensive software solution.

In the highly regulated and fast-paced field of medical device manufacturing, efficiency, accuracy, and compliance are paramount. Praxedo’s Medical Device Manufacturing Software is designed to streamline your operations, enhance productivity, and ensure adherence to industry standards. With our advanced software solution, you can take control of your manufacturing processes and drive success in the medical device industry.

The benefits of medical device manufacturing software are immense. By leveraging Praxedo’s software, you can enhance productivity, ensure quality control, and maintain compliance with regulatory requirements.

Praxedo’s software provides advanced features that help you automate and optimize your medical device manufacturing operations. From real-time monitoring of production lines to intelligent resource allocation, our software ensures that your operations run smoothly and efficiently. By streamlining your workflows, you can minimize errors, improve quality control, and meet the rigorous standards of the medical device industry.

Streamline Operations for Medical Device Manufacturing

Adhering to industry standards is a critical aspect of any air duct cleaning service.

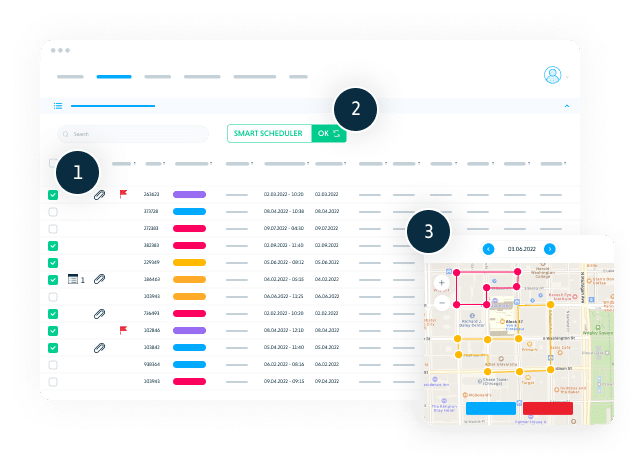

Unlock the full potential of your medical device manufacturing operations with Praxedo’s software. Our solution enables you to streamline scheduling, optimize workflow management, and ensure compliance throughout your manufacturing processes.

Praxedo offers a comprehensive field service management (FSM) software solution specifically tailored to meet the unique needs of medical device manufacturers. Our software empowers you to optimize your operations, enhance productivity, and deliver high-quality medical devices to the market. With Praxedo, you can streamline scheduling processes, improve resource allocation, and ensure timely completion of tasks.

Why Can You Trust Praxedo?

Features for Medical Device Manufacturing

Enhanced Quality Control and Compliance

– Quality Control: Praxedo’s software includes robust quality control features that enable you to implement stringent quality assurance processes. From inspections to testing and audits, you can ensure that your medical devices meet the highest standards.

– Regulatory Compliance: Maintain compliance with regulatory requirements through Praxedo’s software. Our solution helps you track and manage documentation, ensure traceability, and demonstrate adherence to industry regulations and standards.

– Quality Control: Praxedo’s software includes robust quality control features that enable you to implement stringent quality assurance processes. From inspections to testing and audits, you can ensure that your medical devices meet the highest standards.

– Regulatory Compliance: Maintain compliance with regulatory requirements through Praxedo’s software. Our solution helps you track and manage documentation, ensure traceability, and demonstrate adherence to industry regulations and standards.

Show less

Seamless Integration and Data Analytics

– Seamless Integration: Praxedo’s medical device manufacturing software seamlessly integrates with other systems such as ERP, MES, and quality management software. This integration enables smooth data exchange, synchronized processes, and improved overall operational efficiency.

– Data Analytics: Leverage the power of data analytics to gain insights and drive continuous improvement in your manufacturing operations. Praxedo’s software provides robust reporting and analytics capabilities, allowing you to monitor KPIs, identify trends, and make data-driven decisions to optimize your medical device manufacturing processes.

– Seamless Integration: Praxedo’s medical device manufacturing software seamlessly integrates with other systems such as ERP, MES, and quality management software. This integration enables smooth data exchange, synchronized processes, and improved overall operational efficiency.

– Data Analytics: Leverage the power of data analytics to gain insights and drive continuous improvement in your manufacturing operations. Praxedo’s software provides robust reporting and analytics capabilities, allowing you to monitor KPIs, identify trends, and make data-driven decisions to optimize your medical device manufacturing processes.

Show less

Real-time Monitoring

Gain real-time visibility into your production lines and monitor key metrics such as equipment performance, production rates, and quality control. Identify bottlenecks, proactively address issues, and optimize production efficiency.

Gain real-time visibility into your production lines and monitor key metrics such as equipment performance, production rates, and quality control. Identify bottlenecks, proactively address issues, and optimize production efficiency.

Show less

Seamless Integration with Your Existing ERP/CRM/Accounting Software

Ready to Transform Your Medical Device Manufacturing?

Articles from our experts

Ready to take the next step?

Contact us and we’ll help you schedule your next route.